About Dock Levelers

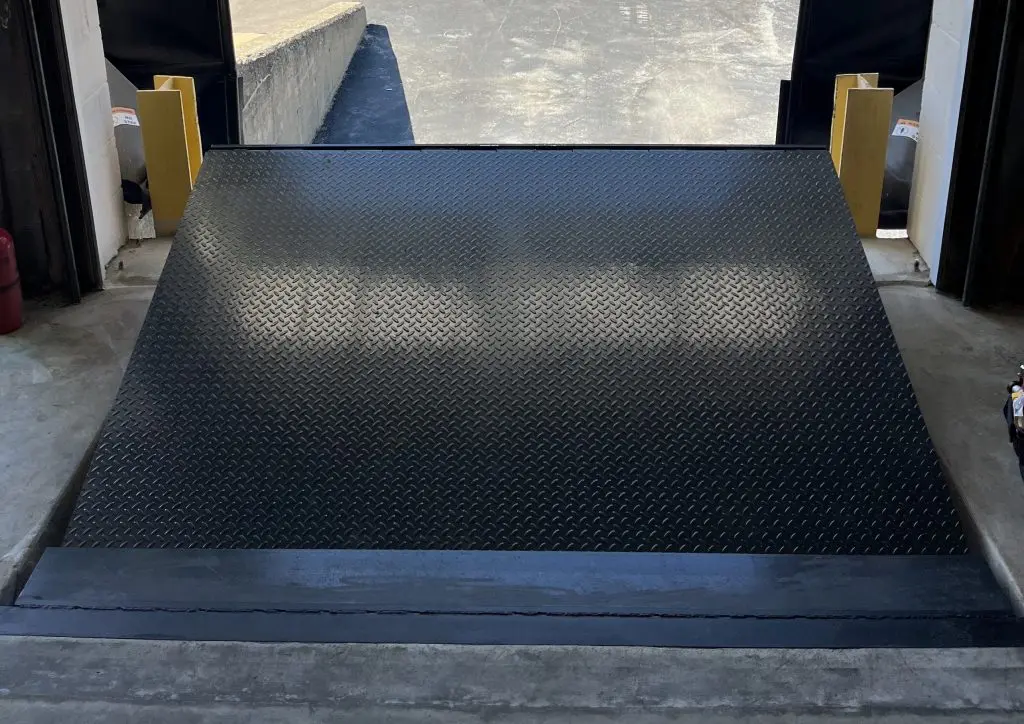

Efficient and safe loading and unloading are the lifeblood of any successful distribution or manufacturing operation. At the heart of this process is the dock leveler, an essential device used at loading docks to bridge the height gap between a truck trailer and the dock floor.

Dock levelers create a smooth and stable transition, allowing goods, materials, and other items to be transferred efficiently from the trailer to the dock and vice versa.

There is a range of dock leveler solutions, from hydraulic and mechanical to vertical storing and air-powered models, designed to boost your productivity, enhance safety, and streamline your entire logistics workflow.

Dock Leveler Solutions

Pit Mounted Dock Levelers

Edge-of-Dock Levelers

Benefits

Enhanced Safety

Dock levelers create a smooth, stable bridge between a warehouse floor and a truck bed, eliminating the hazardous gap and height difference. This prevents accidents like forklift tipovers, product damage, and injuries to workers from falls or uneven surfaces.

Improved Efficiency and Speed

By creating a seamless transition, dock levelers allow forklifts, pallet jacks, and hand trucks to move on and off trailers quickly and without interruption. This significantly reduces loading and unloading times, resulting in faster turnaround for trucks, higher throughput, and more efficient labor utilization.

Versatility and Accessibility

Dock levelers can accommodate a wide range of vehicle types and heights, from standard semi-trailers to smaller box trucks. This flexibility ensures that your loading dock can handle various deliveries and shipments, making your operation more adaptable to different logistics partners and needs.

Product Protection

A smooth, level surface minimizes the jarring and jolting of products during transit between the dock and the vehicle. This helps prevent product damage, especially for fragile or sensitive goods, and reduces the cost associated with damaged inventory.

Optional Variety

Dock levelers come in many varieties, such as pit-mounted, edge-of-dock, and vertical storing, with additional options in mechanism type, including mechanical, hydraulic, and air-powered options.