Defining Material Handling

Material handling is defined as the process of moving, storing, protecting, and controlling materials throughout the supply chain. It is the lifeblood of the supply chain, ensuring that materials and goods are seamlessly moved, stored, and safeguarded at every step. A successful material handling operation places the right materials in the right place, at the right time!

Types of Material Handling Solutions

Material handling solutions are needed in any facility whether it be manufacturing, warehousing, distribution, cold storage, or any other industry. Anything that needs to be lifted, stored, rotated, automated, safeguarded, separated, or organized can benefit. The main types of solutions include:

- Automated Solutions: The new age of material handling! This includes solutions like automated storage, conveyor systems, vertical lift modules, stretch wrap machines, and robotic palletizers.

- Ergonomic Lifting Solutions: Solutions that keep workers from injuring themselves due to repeatedly lifting heavy objects or working at awkward angles. Solutions like cranes, lifts, and lift tables come to mind here!

- Safety Solutions: One of the most important categories! Guarding, markings, rack guards, bollards, you name it. Anything that addresses the safety of the facility and its staff fits into this category.

- Separation Solutions: Mainly associated with wire cages and modular structures, these solutions provide security and separation to any process they are a part of.

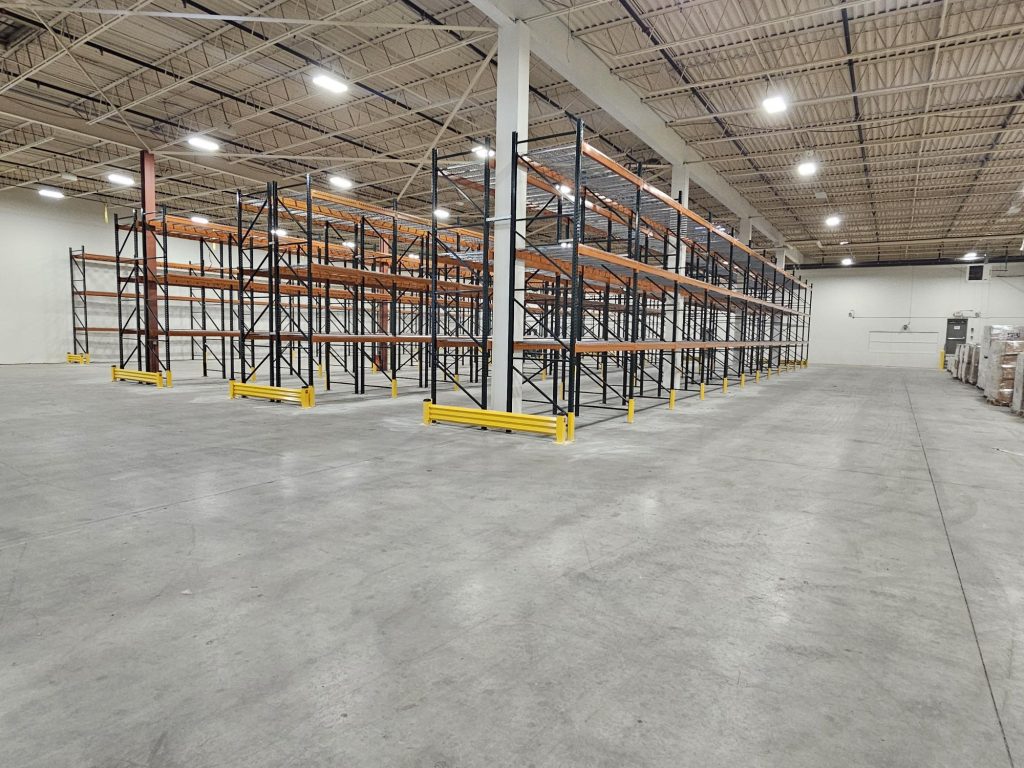

- Storage Solutions: This is where the bulk of material handling items fit into, as storage is such a large part of material handling. Solutions such as mezzanines, racking, automated storage, and shelving all fit well in this category.

While these are the main areas of material handling, there is so much more to discover as the industry is forever changing and updating to implement more efficient solutions for the most forward-thinking facilities!

Benefits of Material Handling

Safety

The most important benefit of using material handling equipment is improving the safety of your workers and facility. Manually handling materials can pose significant risks of injury, but with the right equipment, these dangers are drastically reduced. Utilizing solutions like ergonomic ergonomic lifts, material lifts, conveyors, and cranes can help alleviate the need for manual lifting.

Protecting workers in high-traffic areas where forklifts and heavy equipment operate is also important. With strategically placed markings and guarding solutions, you can create designated paths and marked safe zones throughout the building. Impact guarding, machine guarding, and bollards also help to protect your facility assets from costly accidents.

Efficiency

In addition to boosting safety, material handling equipment plays a pivotal role in enhancing efficiency. A well-integrated system and carefully planned layout can streamline the flow of goods throughout the facility.

Some examples can be seen in automating your process with solutions, such as a conveyor system, to speed up your overall operation as products and parts reach their destinations faster and more reliably. For vertical transport, a vertical reciprocating conveyor (VRC) offers a quick and effective solution for moving materials between floors, keeping your workflow smooth and uninterrupted.

Integrating multiple solutions into a single system or process can overall create a more efficient work environment as these solutions work together to complete that specific process or job.

Space Utilization

Vertical space within the facility is majorly under-utilized by many facilities today. This space is usually left empty as facilities look to expand operations through ground-level solutions, minimizing the open space of their facility footprint. When it comes to a process like storage, facilities can get a huge boost in floor space with proper space utilization!

Pallet racking and automated storage systems provide this vertical storage! These solutions maximize the storage density of larger items and goods freeing up more ground space on the facility floor.

Shelving, modular drawers, and cabinets offer storage for smaller items such as tools and parts. While not taking up the same level of vertical space as a racking system or automated storage system, shelving drawers and cabinets can keep the smaller items organized and close to processes eliminating unused storage space a more unorganized system may cause.

A mezzanine can also be incorporated into the facility as a means of adding a second level and making use of vertical space for a variety of processes. These solutions can integrate racking, shelving, modular offices, and other solutions into them creating a multi-level operation that takes full advantage of the used space!

Customization

Almost all material handling solutions are highly customizable or have a variety of options associated with them. This way these solutions can be designed to meet the facility’s specific needs! An example of optional variety would be a VRC, offering both hydraulic and mechanical options. An example of full customization would be this VRCs ability to be outfitted with customizable platform sizes, lifting heights, and speeds.

Mezzanines are also highly customizable as they can be implemented as large facility-spanning solutions or even smaller-scale single-application work platforms or structures.

Security

The security of your facility is not to be overlooked or forgotten. Locking down areas, limiting facility access, and keeping track of entrances and exits have become much more important in today’s world. This makes the addition of wire partitions and modular structures such as guard shacks a must-have for many facility managers. These solutions provide a reliable safeguard for facility access, equipment, tools, and materials limiting the risk of items being stolen or misplaced.

In Conclusion

Material handling is essential to the supply chain, ensuring materials and goods are efficiently moved, stored, and protected. It plays a pivotal role in any industry as it focuses on improving safety, efficiency, space utilization, and security. Businesses can reduce injury risks, streamline processes, and even save on overall costs by utilizing the right solutions for their operation!

There are so many different categories and specific solutions that it can be hard to know what to implement, and even what to implement first if you are starting with a brand new facility. We provide free consulting with our clients on how to best implement these solutions so that they can have the best and most efficient facility processes for their business. Contact us if you are looking for assistance on your next project, or even if you need information or consulting assistance!