LONDONDERRY NH – JULY 2025

Overview

When we mention loading dock & door, it is common for people to think of the loading dock area. However, most people forget the importance of the “& door” reference, as this covers not only dock entrances but any facility access point!

For facility managers, securing these access points with proper solutions is a must for sustaining effective daily operations. Overhead doors provide this security and can come in many different sizes, shapes, and styles, depending on the need.

About Overhead Doors

Overhead doors can be simple or complex solutions. With benefits and options such as enhanced security features, fast opening speeds, or increased durability and long cycle times, there is a door for any situation.

The main types of overhead doors commonly used are sectional doors, steel roll-up doors, and high-speed fabric/rubber doors.

Each of these excels in specific applications. However, they are still versatile enough to be used in a variety of ways.

Sectional Doors

Sectional doors consist of multiple horizontal panels connected by hinges, offering a balance of durability, cost-effectiveness, and reliability. These panels can be made from various materials, including aluminum, insulated or non-insulated steel, and galvanized steel.

For facilities requiring visibility, a full view or clear door that utilizes windowed panels and an aluminum or steel frame can be implemented. These solutions allow natural light to pass through while maintaining durability and reliability.

Most sectional doors utilize a curved or vertical track, requiring sufficient vertical or horizontal space to fit the tracks. In areas with limited space, a Vertistack system can be used, stacking panels directly above the opening and eliminating the need for traditional tracks.

While sectional doors and steel roll-up doors share many of the same functions, sectional doors are usually the go-to choice at loading docks due to their cost efficiency. They can be used for interior-to-interior and interior-to-exterior operations of the facility, but it usually comes down to customer preference and space constraints.

Steel Roll Up Doors

Steel roll-up doors are made of metal slats that roll up into an overhead coil, making them a great option for facilities with limited overhead space. These metal strips, usually made from stainless steel, galvanized steel, or aluminum, free up overhead space by eliminating the need for bulky tracks that something like a sectional door may require.

Steel roll-up doors provide outstanding security, durability, and longevity, all while being easy to operate. While they may come at a higher price point than sectional doors, many find the added benefits well worth the investment, particularly in applications where either option could be used.

The main types are steel roll-up doors are:

High-Speed

A door with high cycle rates and maximum efficiency. Powered by a direct drive operator, these doors can open as fast as 24 inches per second, ideal for high-traffic accessways where speed is essential.

A door with high cycle rates and maximum efficiency. Powered by a direct drive operator, these doors can open as fast as 24 inches per second, ideal for high-traffic accessways where speed is essential.

Fire Rated

Engineered to protect property and staff, these doors provide a critical barrier by sealing off and isolating incidents. They can be integrated with the building’s fire alarm system or equipped with a fusible link to automatically shut the door in extreme heat.

Intumescent seals are often used to close any gaps around the frame of the door to stop the spread of fire and smoke for up to four hours.

Insulated Steel

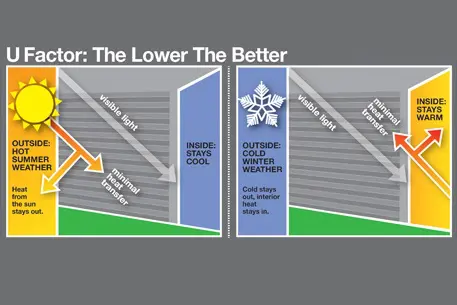

Offers a combination of strength, energy efficiency, and durability. These doors are designed with foamed-in-place insulation enclosed between two layers of formed steel.

This helps regulate temperatures, reduce heat transfer, and improve overall thermal performance. Many models also include a perimeter sealing system, making them a practical choice for facilities looking to maintain climate control and enhance security.

Security Steel

Offers superior protection against unwanted entry, burglary, and destructive vandalism. High-security doors utilize interlocking slats that contract when closed to create an even surface, removing possible pry points. If someone tries to break in, the slats compress even further, making it even more difficult to breach.

High Speed Fabric/Rubber Doors

High-speed doors are designed for busy environments requiring fast opening speeds and high cycle-times, while also providing separation and energy efficiency. The term “high-speed” refers to their ability to open fast, making them excellent solutions for high-traffic access ways.

Both high-speed fabric and rubber offer different benefits to different applications, but maintain these core benefits! Both are also built with a crash-forgiveness design, allowing them to be quickly reinserted into their tracks after an impact. This feature helps minimize downtime and reduces costly repairs, ensuring operations stay efficient and uninterrupted.

Fabric Doors

High-speed fabric doors are engineered for rapid and reliable operation, making them ideal for environments that require both efficiency and environmental control. Their fast opening and closing speeds help minimize air exchange, supporting temperature stability in coolers and freezers while also improving workflow and reducing energy loss. These doors remain flexible in temperatures as low as -22°F, ensuring dependable performance in cold storage applications.

For more demanding environments, specialized cleanroom doors made with ultra-high molecular weight polyethylene (UHMW) can be equipped with sealing gaskets to regulate air pressure, temperature, humidity, and contamination levels.

Rubber Doors

High-speed rubber doors are constructed with a two-layer system of SBR (Styrene Butadiene Rubber) and EPDM (Ethylene Propylene Diene Monomer), enhancing their weather resistance, UV stability, and longevity.

They excel in heavy-duty applications that see harsh weather and extreme conditions like the mining, energy, manufacturing, and transportation industries. They are also a great choice for parking garages due to their crash-forgiveness.

While they require a higher initial investment, their exceptional durability makes them a long-lasting solution.

Preventative Maintenance & Service

Preventative maintenance is an effective way to keep overhead doors operating reliably and reduce the risk of unexpected breakdowns. Over time, wear and tear can lead to issues such as misalignment, damaged components, or safety concerns if left unaddressed.

Routine inspections and servicing help identify potential problems early, keeping your equipment in good working condition and minimizing downtime. Whether scheduled annually, bi-annually, monthly, or done as a one-time checkup, preventative maintenance supports both safety and long-term performance.

In Conclusion

Overhead doors play a critical role in facility operations, offering secure, efficient access points far beyond just loading docks. From sectional and steel roll-up doors to high-speed fabric and rubber doors, each door type serves specific needs depending on space, speed, and environmental demands. Pairing the right door with consistent preventative maintenance helps ensure long-term reliability and uninterrupted workflow.