Dock Levelers

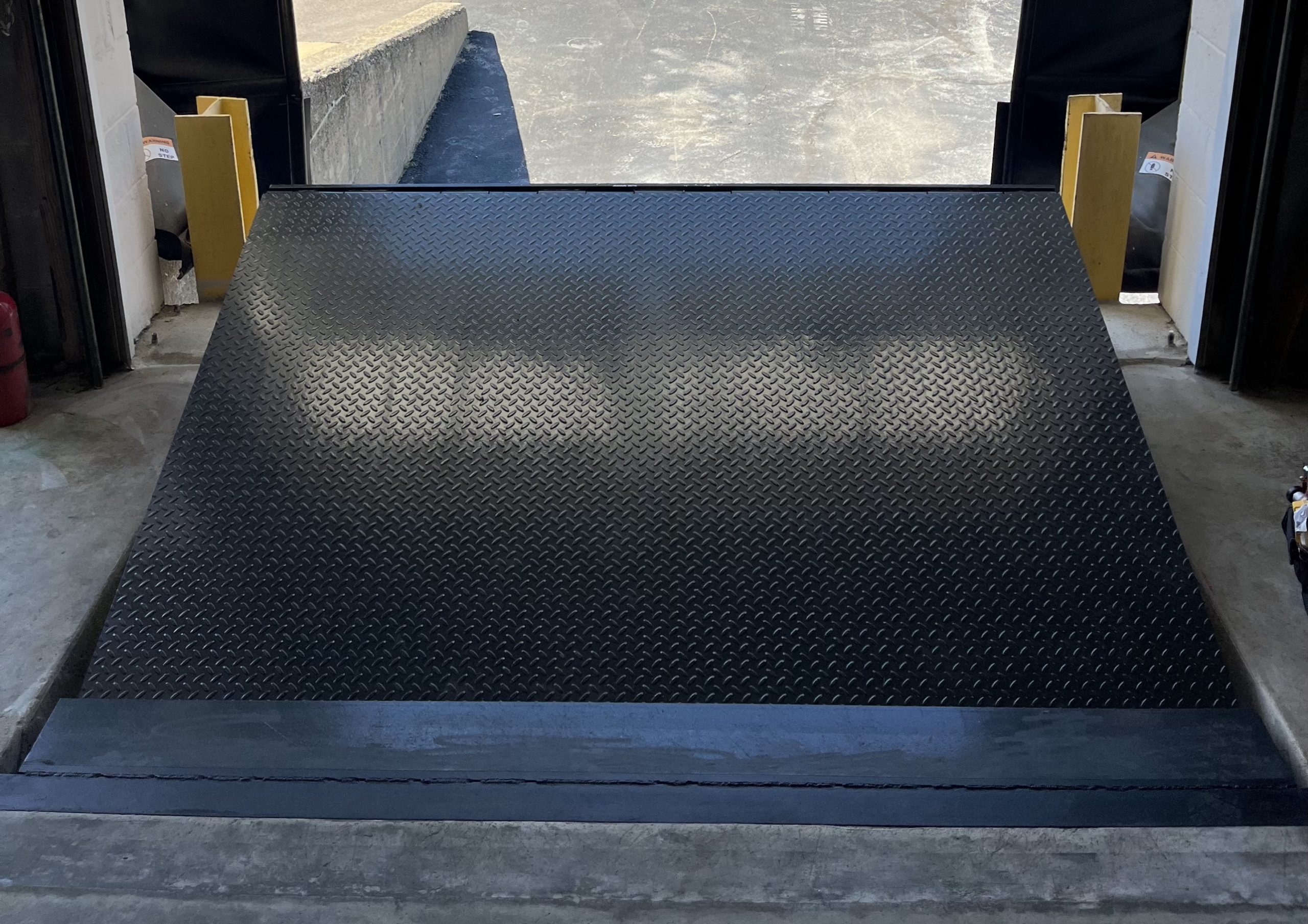

Dock levelers are solutions that bridge the height gap between the dock floor and an incoming truck trailer. They ensure a smooth transition for loading and unloading goods, accommodating various truck heights. The main three types of dock levelers are:Pit-mounted dock levelers

Pit-mounted levelers come with hydraulic, mechanical, and air-powered options, each with their own capacities, price ranges, and benefits.

Pit-mounted dock levelers have the highest price tag for a reason. They can accommodate trucks up to a foot taller or shorter than the dock and have the highest load capacity of the three. They are ideal for facilities that handle heavy duty material and a higher variety of truck heights.

Edge-of-Dock Levelers

Edge-of-dock levelers attach directly to the dock edge, offering a compact and cost-effective alternative to pit-mounted levelers. This speeds up the installation while still making them an efficient and sturdy method for loading and unloading trailers. Available in both hydraulic and mechanical versions, they are ideal for facilities looking for a budget-friendly option that still delivers reliable dock support. However, with the lower price tag comes some limitations.

Edge-of-dock levelers are limited to truck heights of five inches above and below the dock and have lower load capacities than their pit-mounted counterparts.

Vertical Storing Dock Levelers

Vertical storing dock levelers can be installed in a pit or a shelf, both of which take up less space than the traditional pit needed for a pit leveler. Because it is stored in the upright position, cleaning and keeping out pests in the pit is much easier; useful in industries where cleanliness is a requirement, like the food industry.

Vertical storing dock levelers tend to be more expensive than traditional pit levelers with the same capacity due to the unique installation requirements.

Elevating Docks

Elevating docks function as versatile platforms that provide access from the dock to the truck bed, especially useful when traditional pit-mounted or edge-mounted dock levelers aren’t feasible. They are perfect for applications where the dock is at ground level, requiring an elevated platform to reach the truck bed or where the dock is elevated, and goods need to be brought from ground level to dock level. Unlike other dock solutions, elevating docks use the space outside the dock area, offering flexibility in servicing trucks of various sizes.Yard Ramps

Yard ramps offer a versatile solution for facilities without a permanent loading dock or where installing a dock leveler or elevating dock isn’t possible. These portable ramps act as mobile docks, providing a cost-effective way to streamline loading and unloading operations. Their mobility allows them to be easily transferred between dock areas as needed, some are even capable of being attached directly to the trailer, making them ideal for businesses requiring flexibility in their loading and unloading processes.Dock Seals

Dock seals use foam pads to create a tight seal between the dock and trailer, perfect for temperature control. By sealing the dock entrance and trailer tightly, dock seals help maintain consistent indoor temperatures and protect goods from weather exposure. They are compact and do not occupy a lot of space around the dock door. However, dock seals have some limitations. They are limited to certain truck and dock sizes and tend to wear out faster than dock shelters due to the foam pads coming into direct contact with the trailer. They also get compressed into the loading dock area, shrinking the operational space of the door. This can make it tough for forklifts to move in and out without damaging the pads.Dock Shelters

Dock shelters use fabric curtains to enclose the trailer, offering a flexible solution for various truck and dock sizes. While they create a solid barrier against the elements, such as rain and snow, they don’t offer the same level of temperature control as dock seals. Additionally, they take up more space around the dock door, which may be a problem in tight spaces. Both seals and shelters are a great option for keeping out the elements, such as rain and snow, however it is important to know the benefits and drawbacks of each to choose the right solution for your facility!Truck Restraints

Truck restraints are an essential safety feature for any loading dock, keeping trailers locked in place during loading and unloading. These solutions latch onto the carrier trailer and act as a resisting force, keeping the carrier in place. Applications with sloped entrances to the dock can significantly benefit from a restraint solution that keeps the trailer from rolling away and causing potential damage.Other Safety Solutions

Bollards

Bollards are great for protecting the edges of your loading dock from trucks or forklifts. They can withstand heavy impacts, preventing costly damage to the dock structure or building, and act as a visual guide, helping drivers navigate and align their vehicles accurately during docking.

Guardrails

Guardrails are also a great safety solution for loading docks. By providing a visual boundary, guard rails prevent workers from falling off the edge of the dock and easily outline pedestrian walkways and vehicle paths.

Loading Dock Gates

Loading dock gates are essential for protection, allowing forklifts and personnel to move safely around the dock area. These gates act as an access point barrier to prevent unauthorized access and safeguard while the gate is not in use in the downright position.