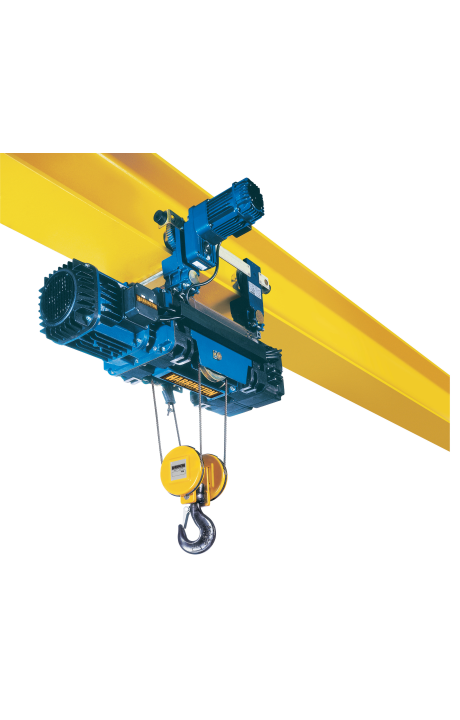

What is a Hoist?

A hoist is an overhead lifting device that uses pulleys, cables, or chains to securely move objects, commonly used in construction and manufacturing to ease the lifting of heavy loads and reduce worker strain. Mounted on the main horizontal beam of the crane, known as the bridge girder, the hoist moves back and forth across its length. Chain hoists are ideal for lifting loads under 5 tons with minimal maintenance, while wire rope hoists handle heavier loads of 5 tons or more. Single-reeved hoists use a single rope on the drum, and double-reeved hoists use two ropes for a true vertical lift. Wider-diameter rope drums in single-reeved hoists reduce hook drift during operation. Hoists are versatile, and used in various industries to lift freight, building materials, engines, and warehouse goods.

Key Features

Lifting Capabilities

Hoists streamline the lifting of heavy loads during building projects, reducing worker strain.Suspension and Height

Hoists are crucial for lifting and moving heavy materials efficiently in warehouses. The three main hoist types; Electric, Pneumatic, and Manual, all have different ways of lifting supplies, what kind, how high, and with different weight capacities.Transportation Assistance

Hoists facilitate the precise transportation of raw materials and finished products between assembly stages.

Hoist Options

While there are many options of hoists, they all fall under one of the three categories: Electric, Pneumonic, and Manual

Electric

Powered by electricity along with chains or a wire rope to lift and lower objects. The advantages of electric hoists have enhanced safety, ergonomics, and productivity levels due to being operated by a push of a button rather than physically cranking a lever or pull chain. Types of electric hoists include:Gear

Powered by a driving gear, one or more driven gears work together to lift the load. This type of mechanical-electric hoist is most commonly found in construction, manufacturing, and material handling industries due to its ability to support heavy loads with the most precision.

Hydraulic

This electric hoist relies on an oil-based piston mechanism instead of a motor system. This configuration allows for the lifting of heavier loads.

Piston

This type of hydraulic-electric hoist is moved linearly by fluid pressure. When force is applied to one point of an incompressible liquid, it shifts the force to the second point and lifts the object. With this configuration, this hoist can lift much heavier loads with a smaller motor in place for compatibility. While hydraulic hoists mainly operate with only hydraulics, piston hoists can make use of a motor in addition to hydraulics.

Pneumatic

These hoists are safer than their electric counterparts and can be used outdoors without special IP ratings. Pneumatic hoists are self-cooling and can be used in hotter environments without compromising performance since they rely on their driven motors and air pumps rather than electricity. Types of pneumatic hoists include:Rotary

This hoist can either be pneumatic or hydraulic, it is equipped with a cylindrical housing containing vanes or blades mounted on an interior rotor, this vacuum system is an ideal choice for industries requiring smooth and controlled lifting with minimal risk of damage, such as material handling, packaging, and automation.

Manual (Mechanical)

Also known as chain falls, these hoists are operated by a hand-operated lifting device. The hand chain controls the lifting and lowering of the supply load. This style of hoist is a good option when working in hazardous areas as it only requires manpower instead of electricity or air. Types of manual (mechanical) hoists include:Lever

Lever hoists are cranked up and down with a lever to move a load, making them great hoist solutions for upward and downward movement, as well as smaller load capacity requirements.

Chain

Chain hoists are operated by a hand chain and are mainly used for much higher load capacities than a lever hoist. They use a pulling force to move the heavy object vertically from one station to the next.