About Conveyor Systems

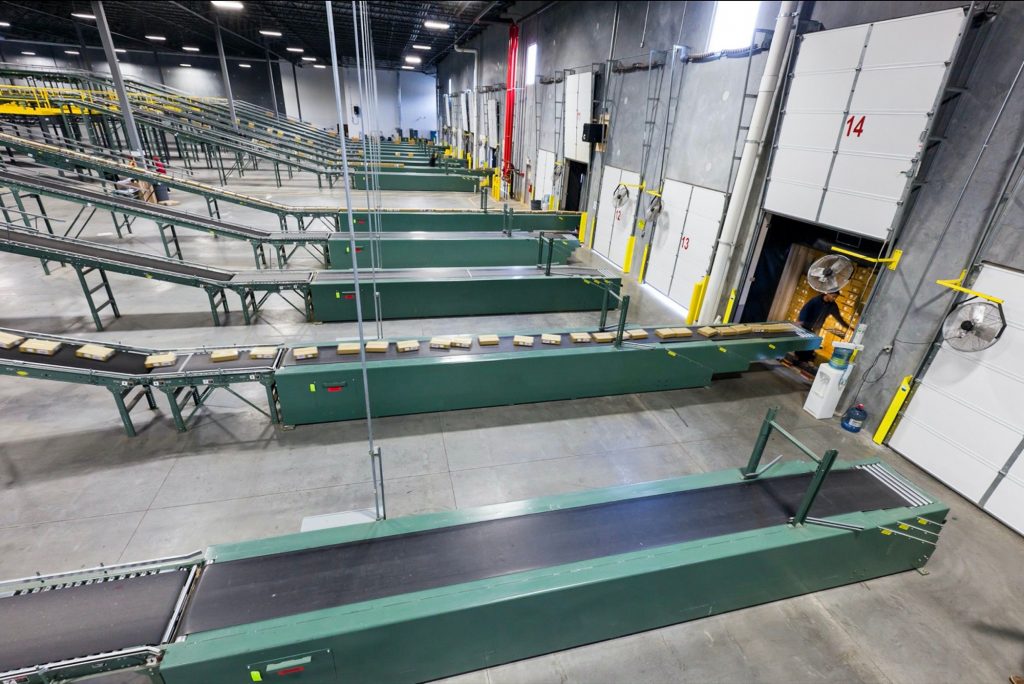

Conveyor systems are one of the unsung heroes of efficient material handling. These sophisticated automated material handling devices are designed to move materials from raw goods and work-in-progress production to finished products.

Conveyor systems are engineered to optimize your processes, boost productivity, and streamline your workflow, no matter the scale or complexity of your needs.

Whether you’re looking to enhance warehouse efficiency, automate manufacturing lines, or simplify distribution, we offer a comprehensive range of customizable conveyor solutions designed to elevate your facility to the next level.

Conveyor Solutions

Conveyor Systems

Benefits

Increased Efficiency

Conveyor systems automate the movement of materials, leading to faster and more consistent throughput compared to manual handling. This optimization of workflow can significantly improve overall operational efficiency.

Reduced Labor Costs

By automating material transportation, businesses can reduce their reliance on manual labor. This leads to lower payroll expenses and can free up personnel for other tasks that require human skills and decision-making.

Improved Workplace Safety

Manually moving heavy or awkward items can lead to injuries. Conveyor systems minimize the need for manual lifting, carrying, and repetitive motions, creating a safer working environment and reducing the risk of accidents and associated costs.

Increased Throughput

Conveyor systems can move a higher volume of materials in a shorter amount of time compared to manual methods. This increased throughput allows businesses to meet higher demands and improve their production capacity.

Adaptable and Customizable

Conveyor systems are highly versatile and can be tailored to specific needs and environments. Their modular design allows for easy modification, expansion, and integration with other automated systems, making them a flexible solution for various industries and applications.