However, while there are OSHA guidelines for handrail and other guarding devices for stairs, mezzanines, and other structures there are no direct guidelines for use of guarding around machinery or forklift paths. Many facility managers simply mark off these areas and pathways with tape or other markings.

However, while there are OSHA guidelines for handrail and other guarding devices for stairs, mezzanines, and other structures there are no direct guidelines for use of guarding around machinery or forklift paths. Many facility managers simply mark off these areas and pathways with tape or other markings.

The Issue with Markings

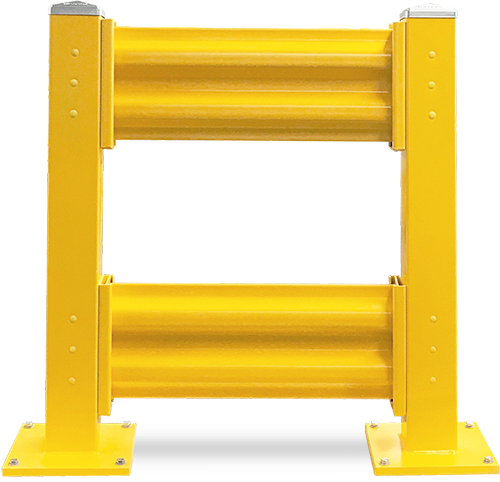

While markings are a cheap and easy way to provide visual ques to mark off areas, they do not offer ANY physical protection to these areas. Through the many day-to-day activities of machine and forklift operators these markings can occasionally be ignored causing potential for injury, damage, or both. There are also occasions where a forklift/machine operator can be distracted or worse, experience a medical issue such as a heart attack, causing them to veer off the marked path. This can lead to the fork truck or piece of machinery entering the safe area outside of the markings causing damage to equipment or injuries to staff. Guardrail helps to provide that physical barrier in case these issues occur. These solutions will absorb the impact as opposed to the impact going into other equipment or facility staff.Understanding Impact Ratings

It is important to understand that guardrail can manufactured to consist of different impact ratings and that these impact ratings determine the guardrail’s resistance to force. Many manufacturers build guardrail with an impact rating of 10,000 pounds at 4 mph. With forklifts generally weighing between 8,000 – 10,000 pounds this guardrail will prevent the forklift from driving through it at a max speed of 4 mph.

Since this is the case, what is the reason for manufacturers to build higher impact rating guardrail such as 13,000 pounds? The answer to this is the level of deflection (push-back) on the guardrail. Typically, 10,000 pounds impact rated guardrail will deflect 12-15 inches back when struck, while 13,000 pounds impact rated guardrail will only deflect 10 inches or less!

These few inches matter to many facility managers trying to make the most out of their floor space. Inches can add up and allow equipment to be placed closer to forklift paths and other guarded areas making a huge difference in your facility’s use of floor space.

Many manufacturers build guardrail with an impact rating of 10,000 pounds at 4 mph. With forklifts generally weighing between 8,000 – 10,000 pounds this guardrail will prevent the forklift from driving through it at a max speed of 4 mph.

Since this is the case, what is the reason for manufacturers to build higher impact rating guardrail such as 13,000 pounds? The answer to this is the level of deflection (push-back) on the guardrail. Typically, 10,000 pounds impact rated guardrail will deflect 12-15 inches back when struck, while 13,000 pounds impact rated guardrail will only deflect 10 inches or less!

These few inches matter to many facility managers trying to make the most out of their floor space. Inches can add up and allow equipment to be placed closer to forklift paths and other guarded areas making a huge difference in your facility’s use of floor space.

Get Your Guardrail Quickly with Wildeck

So, you have decided to implement guardrail in your facility or even add more of it to your already existing guarding. How quickly can you get it ordered and installed? Wildeck, Inc. is a well-known manufacturer of guardrail and offers a 2-day quick ship program for its guarding products! Any stocked guarding orders less than $5,000 list price is available to ship in 2 days. Once the guarding is ordered our Bode in-house installation team can then implement it in desired areas around your facility. Leaving you with a finished safety solution that will provide you with peace-of-mind and increased safety for years to come! To learn more about Wildeck’s 2-Day shipping program visit their site: https://www.wildeck.com/?press_releases=now-available-2-day-shipping-for-guarding-products

To learn more about Wildeck’s 2-Day shipping program visit their site: https://www.wildeck.com/?press_releases=now-available-2-day-shipping-for-guarding-products