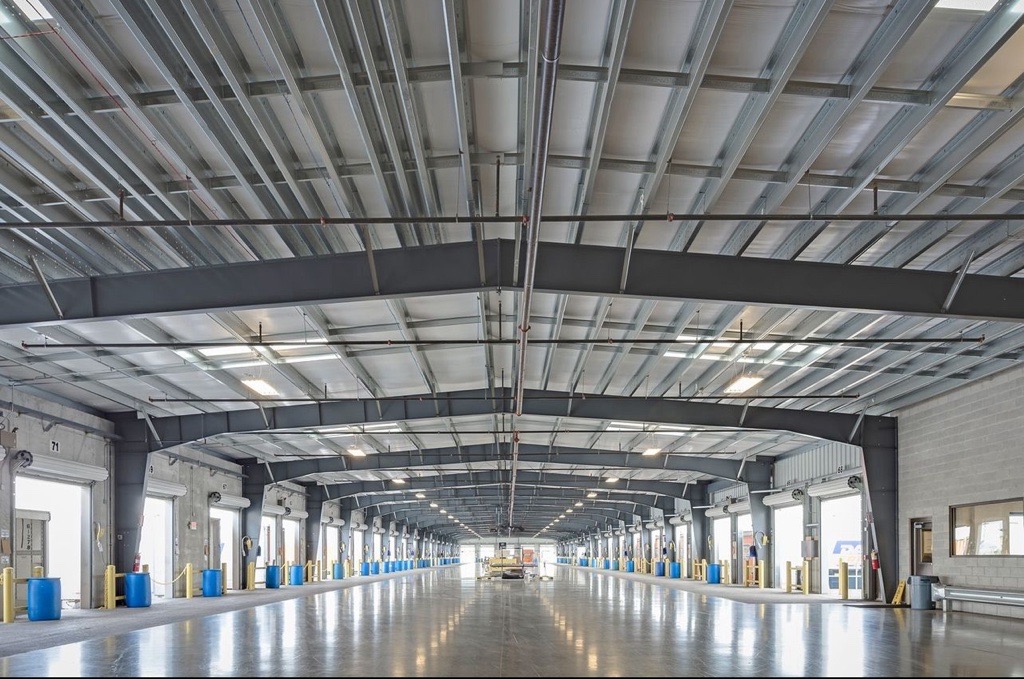

Swift and Seamless Assembly

PEMBs have a swift and seamless assembly process. By utilizing pre-fabricated components, the construction process is expedited, which keeps up with the demands of modern construction. The metal components are assembled on-site in an effortless manner. This assembly process enhances efficiency and takes away the complexities of traditional construction methods.