Automate the Process with Conveyors

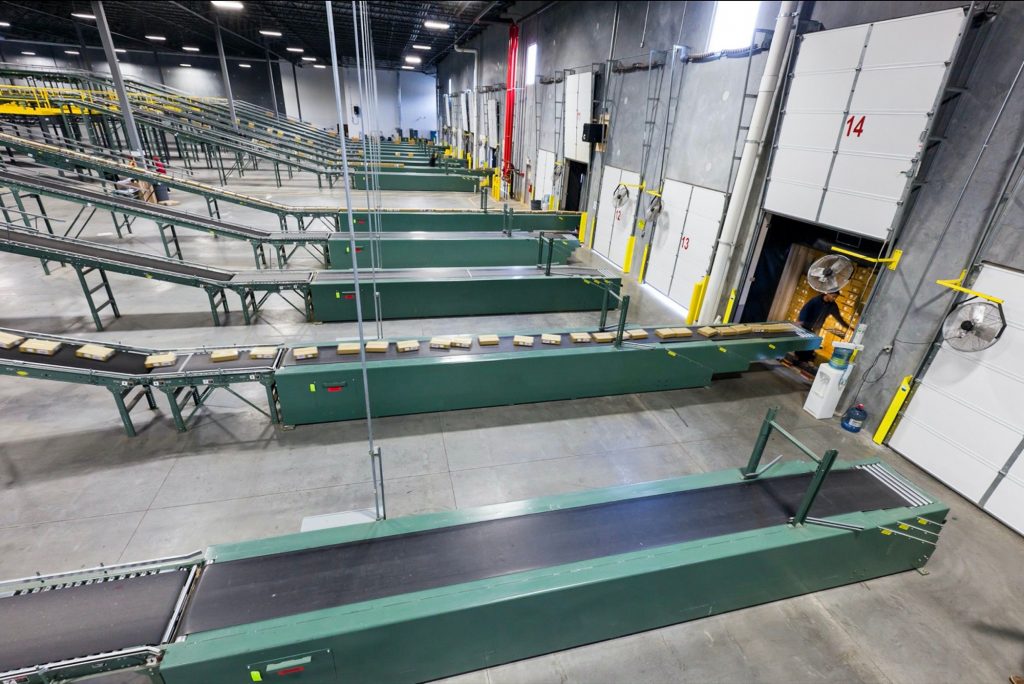

To truly increase efficiency, safety, and time management a telescopic conveyor is the best option!

These conveyors are designed to extend into trailers and assist in maneuvering products in or out. This allows just one or a few employees to stay at the end of the conveyor and begin unloading or loading as the conveyor moves items from one end to the other.

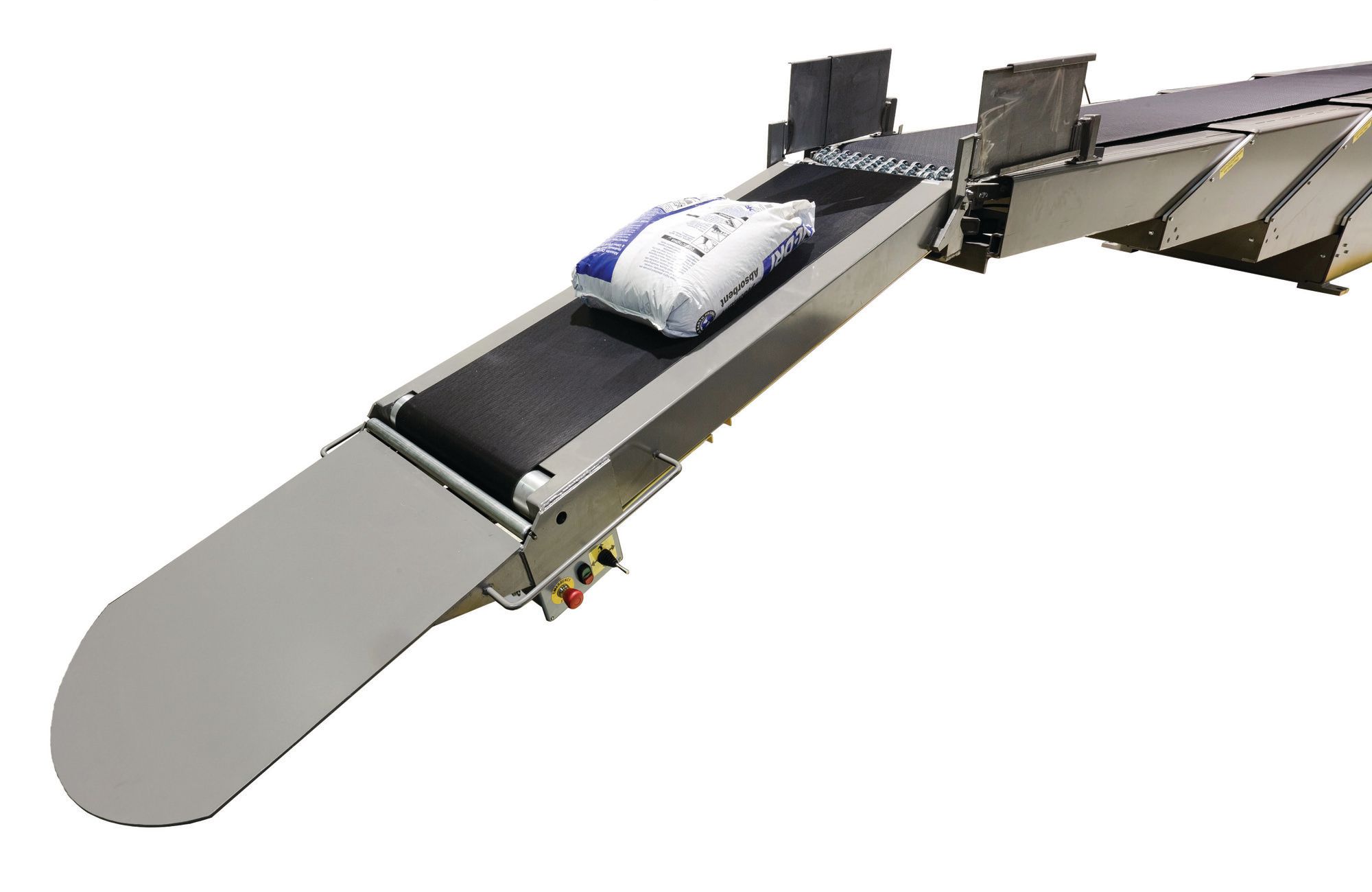

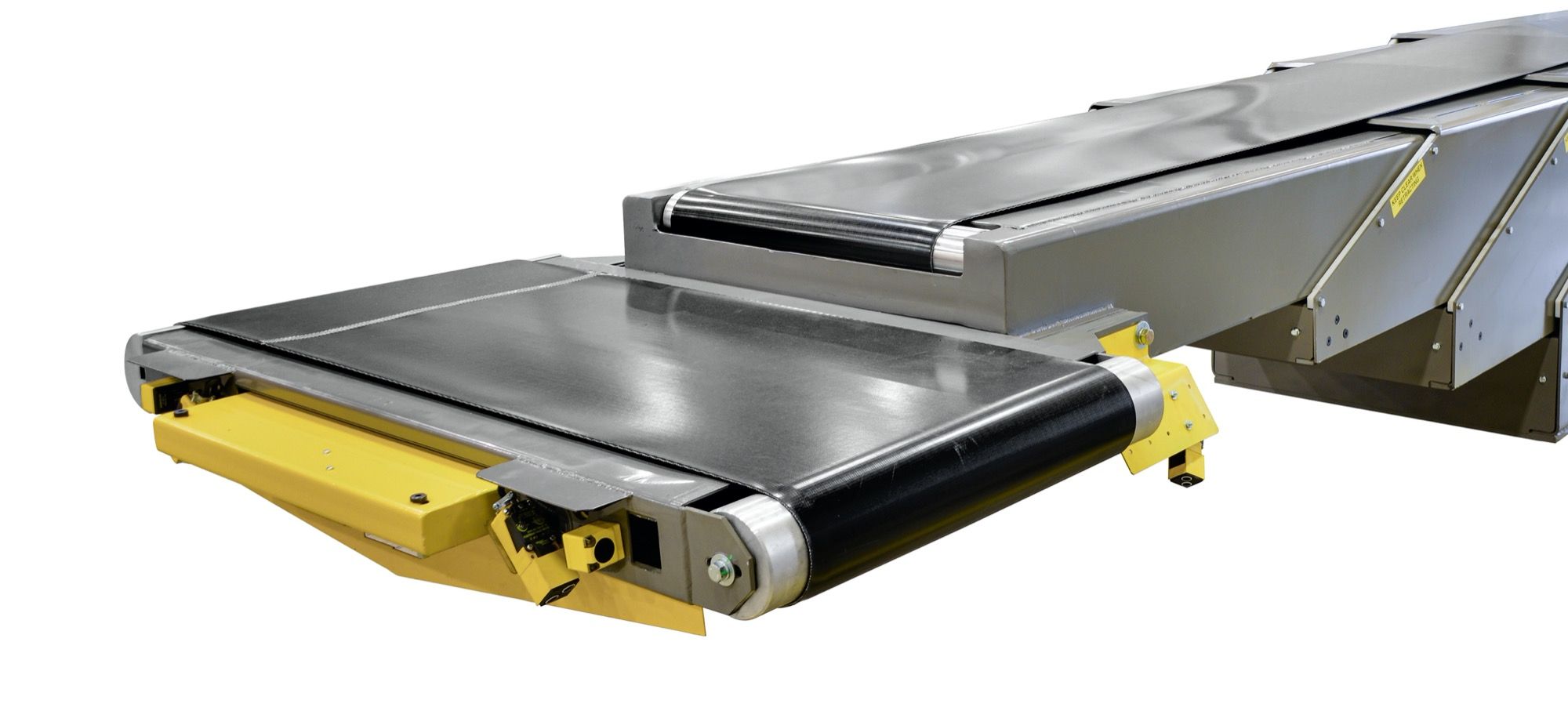

FMH Conveyors’ Maxxreach telescopic conveyor offers this ability to transport goods in and out of the trailer while also presenting other key benefits to your dock loading or unloading operation.

The Maxxreach telescopic conveyor consists of a durable design that creates long-lasting solution even under the toughest facility environments. While being a durable solution, this conveyor also provides easy operation to the user with convenient controls for movement, lights, and belt operation.

Its ergonomic design contributes to the benefit of making it easier to use for staff as the conveyor’s height keeps boxes at an ergonomically efficient and safe position for loading and unloading.

To truly increase efficiency, safety, and time management a telescopic conveyor is the best option!

These conveyors are designed to extend into trailers and assist in maneuvering products in or out. This allows just one or a few employees to stay at the end of the conveyor and begin unloading or loading as the conveyor moves items from one end to the other.

FMH Conveyors’ Maxxreach telescopic conveyor offers this ability to transport goods in and out of the trailer while also presenting other key benefits to your dock loading or unloading operation.

The Maxxreach telescopic conveyor consists of a durable design that creates long-lasting solution even under the toughest facility environments. While being a durable solution, this conveyor also provides easy operation to the user with convenient controls for movement, lights, and belt operation.

Its ergonomic design contributes to the benefit of making it easier to use for staff as the conveyor’s height keeps boxes at an ergonomically efficient and safe position for loading and unloading.