About the Client

The filter division of a Motion & Control Technologies manufacturer in Haverhill, MA was in need of machined parts to assist in their production lines as they relocated their machining operations back to the US.

The client would need additional assistance in manufacturing and storing these parts while also ensuring no stoppages or hold ups in the production process.

Client services include:

- Aerospace systems/parts

- Bioprocessing/medical solutions

- Precision Engineering & Manufacturing

- Refrigeration & AC

- Motion & Control Technologies

The Challenge

The client sought to relocate their machining and manufacturing operations back to the United States from overseas. With this initiative in mind, the company’s filter division would need some assistance with base components in order to complete tasks.

The Solution

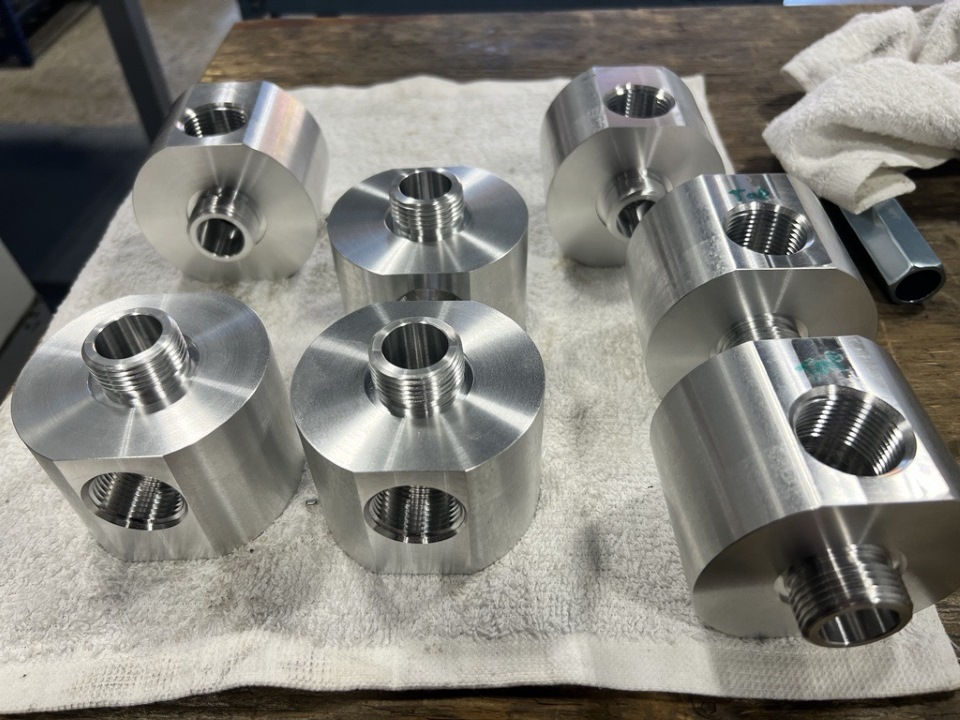

BODE would manufacture and warehouse these base machined components in its precision machine facility, as well as coordinate monthly runs of the machined components with the client, ensuring no stoppages or holdups in production.

“The detailed report is great, I wish all of our suppliers provided this level of detail!”

Harrison MacDonald

Materials Manager, Industrial Gas Filtration and Generation DivisionPhase II:

Finishing

BODE drops off and picks up these parts for the different finishing requirements as needed through production. Once coatings are complete and the parts are back in-house, final machining and inspection occurs prior to packaging for delivery or inventory.

Click on a photo to view full-sized.

Major Products Selected

We chose industry-best products according to the specific needs of the project.

- Machining

- Anodizing

- Warehousing

- Just-in-time deliveries

- Inventory Management