About the Client

This architectural stone mason located in Sudbury, MA is a multi-generational family business specializing in architectural stone masonry.

They offer their expertise to a large variety of projects, creating beautiful custom stonework for residential, commercial, and institutional settings.

Client Services Include:

- Architectural Stonework

- Granite, Limestone, Bluestone

- Sitework

- Consulting

- Fabrication

- Custom Projects

The Challenge

The client was looking to expand their stone-cutting business with a new stone-cutting CNC system. The CNC had specific requirements pertaining to the flow of large blocks entering and exiting the system, plumbing entering the machine, floor drainage, water clarification, overhead loading, and overall height of the system.

This was a large capital investment for the client and they wanted a building to match the impressive quality of the new CNC machine.

The Solution

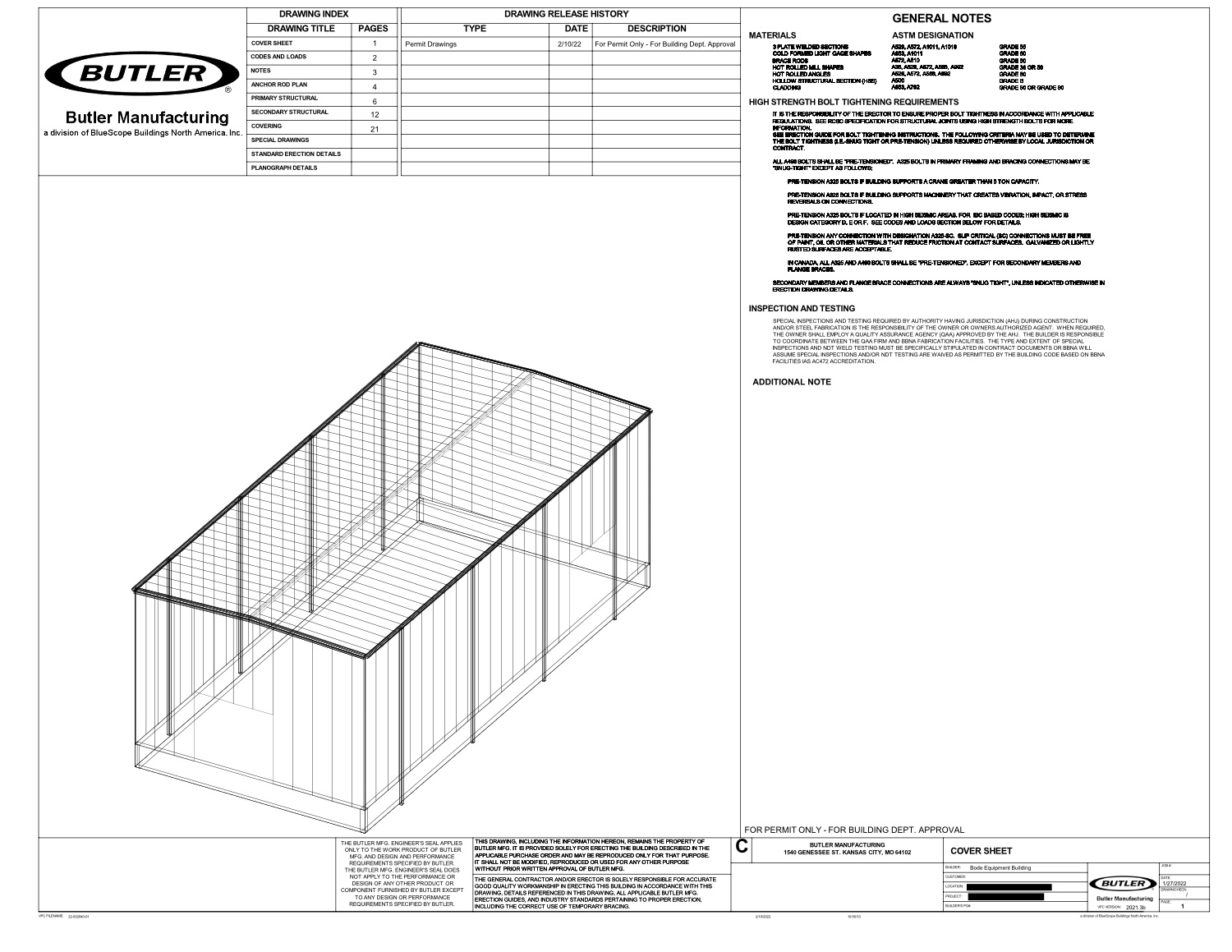

BODE implemented a Butler Classic II Pre-Engineered Metal Building that included their best-in-class MR24 roof.

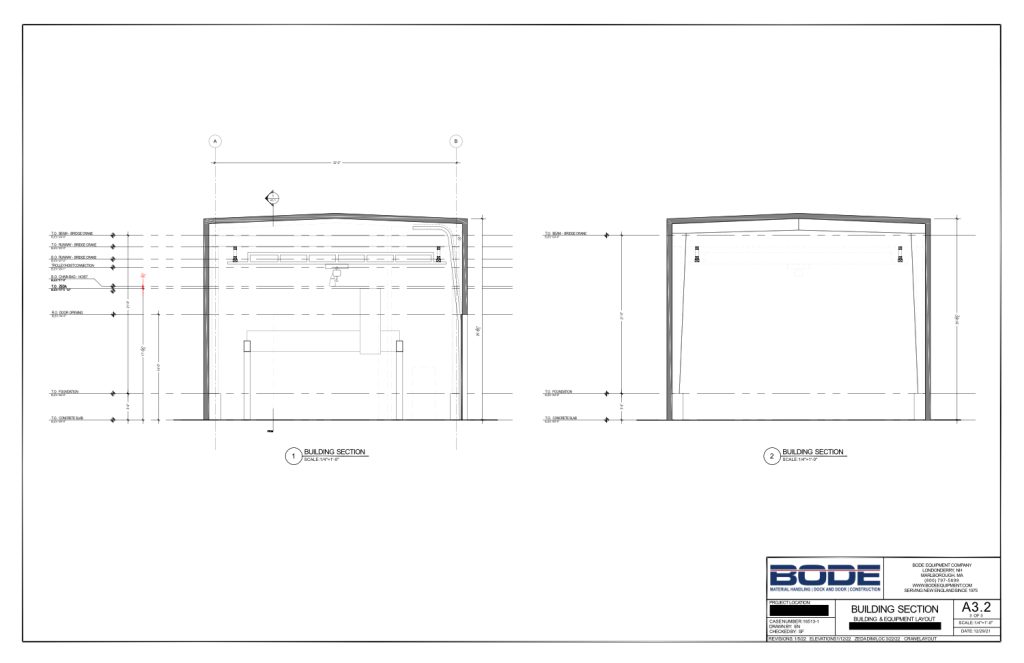

Three large 12’ wide x 14’ high Clopay sectional doors with custom tracks that allowed the door to run between the bridge crane steel and building steel.

A Spanco crane system was 26’ wide x 78’ long x 18’ high with fixed bus bar festooning and an air hose to support the vacuum system picking the cut stones.

As the project was developing the client decided to add an addition to store a new water treatment system

Eric Nickerson

Project Manager, BODEPre-Construction Phase:

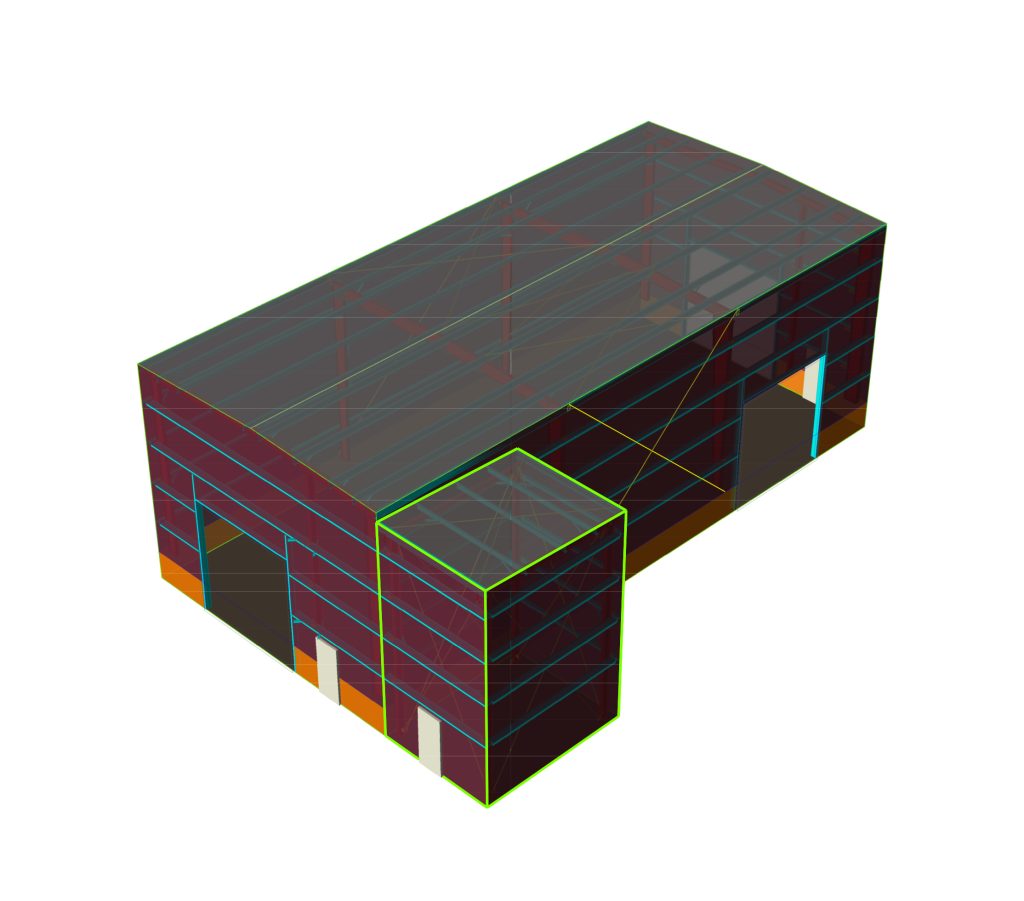

BODE Renderings

Our team first modeled the Butler building, CNC, sectional doors, and bridge crane in AutoCAD to ensure the integration of systems without any interference.

This was a CAD-heavy project, a lot of attention to detail was needed to make sure the crane, doors, and building would all be correct and work together.

Click on a photo to view full-sized.

Pre-Construction Phase:

Architectural Renderings

The foundation plans to support the building, new machine, and bridge crane took over a month to design. We created renderings to get both the client’s and town’s approval, as well as to understand the scope of the project.

Click on a photo to view full-sized.

Construction Phase:

Assembly & Erection

We started with building the foundation, concrete pouring, and installing the CMU knee wall. The site was a complicated area to work within therefore we had a project manager on-site at all times during this process.

Once these steps were complete we then were able to put up the Butler steel frame.

Click on a photo to view full-sized.

Construction Phase:

Sectional Doors, Crane, and Building Installation

Once the steel structure was in place we then moved on to putting up parts of the crane, such as the columns for the bridge, before putting the wall and roof systems on the building. This would create a quicker and easier process of getting the crane implemented inside the building.

Once the walls and roof systems were installed, we put up the sectional doors and built up the interior structure that the new CNC machine would ride on.

Click on a photo to view full-sized.

Construction Phase:

Final Construction

The clients selected a traditional New England barn-style color red with white trims. This created an excellent-looking finished structure!

As the project was developing the client decided to add an addition to store a new water treatment system. This addition was built with conventional light wood construction integrating a steel roll-up door from Cookson.

Click on a photo to view full-sized.

Major Products Selected

We chose the best solutions for the job and made sure everything would fit and work together to avoid any issues during the construction process or after its completion.

- Butler Classic II Pre-Engineered Metal Building

- Clopay Sectional Overhead Doors

- LiftMaster Door Operators with Chain Hoist Override

- Spanco Bridge Crane

- Harrington Hoist System