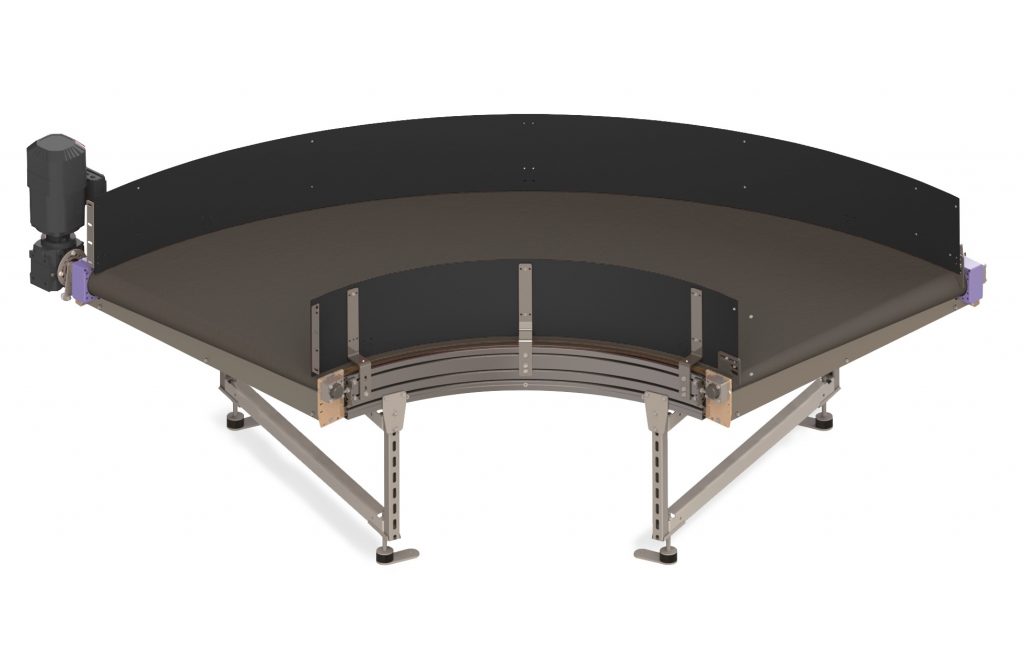

Curved Belt Conveyors

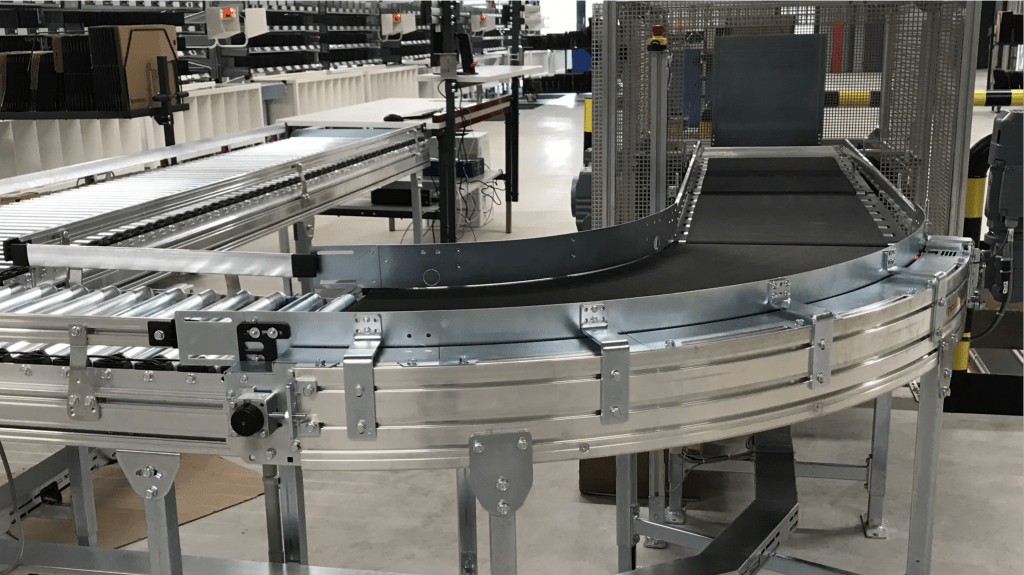

Curved belt conveyors offer this ability to move around corners as they connect to existing conveyor sections. These solutions provide materials a way of turning these corners with no interruption in the conveyor process. This is due to the curved belt conveyor’s ability to seamlessly integrate with adjoining sections of the existing conveyor solution. Whether it be a 180 degree turn or a full 360-degree turn, these curved belt conveyors can change the direction of the conveyor system with ease!The CBC120 from FMH Conveyors

FMH Conveyors offers a curved belt conveyor known as the CBC120. This solution is designed for versatility, maximizing available space, and enhancing your conveyor setup.

This conveyor is supports heavy loads and creates a solution with space utilization in mind. Meaning that the CBC120’s curved design eliminates extraneous conveyor lengths and handling times!

FMH Conveyors offers a curved belt conveyor known as the CBC120. This solution is designed for versatility, maximizing available space, and enhancing your conveyor setup.

This conveyor is supports heavy loads and creates a solution with space utilization in mind. Meaning that the CBC120’s curved design eliminates extraneous conveyor lengths and handling times!

The Benefits

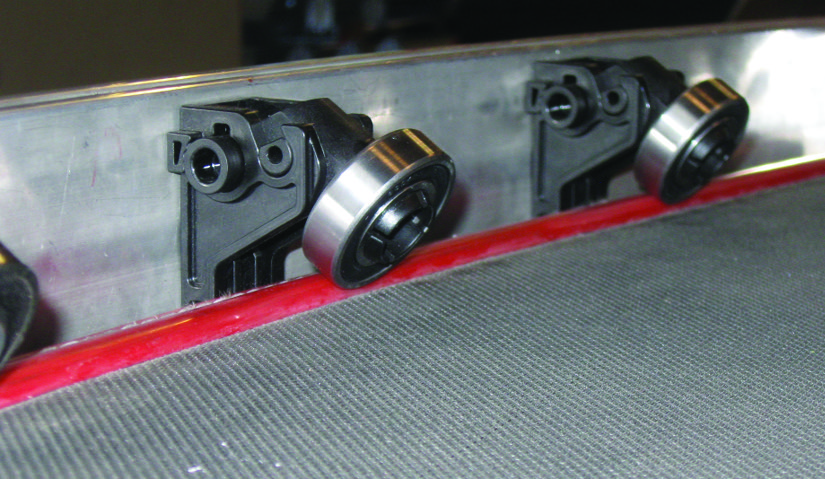

Much like other curved belt conveyors of its kind the CBC120 assists in supporting loads around corners and obstacles in the facility. However, it takes on other advantages as well! The first of these advantages is its exceptional durability. This solution is designed for high-volume, heavy-duty applications making them very reliable in situations involving a lot of material movement. The next advantage is its performance-focused engineering which contributes to its lower maintenance requirements when compared to other conveyors. This engineering can be seen with the conveyor’s guiding profiles that are five-times stronger than traditional belt beading, which commonly break or require maintenance.

The third advantage is its quick belt changing meaning that in scenarios where belt changing is required, its modular design allows for a speedy resolution and minimal downtime. Where normally it could take a few hours to change the belt, the CBC120’s belt can be changed in as little as 15 minutes!

The next advantage is its performance-focused engineering which contributes to its lower maintenance requirements when compared to other conveyors. This engineering can be seen with the conveyor’s guiding profiles that are five-times stronger than traditional belt beading, which commonly break or require maintenance.

The third advantage is its quick belt changing meaning that in scenarios where belt changing is required, its modular design allows for a speedy resolution and minimal downtime. Where normally it could take a few hours to change the belt, the CBC120’s belt can be changed in as little as 15 minutes!

The last advantage is the CBC’s modular design making it a huge benefit for facilities in need of fast and efficient setup and integration into their system. This modular design also contributes to the quick belt replacement during the rare occasions when maintenance is needed on the belt.

The last advantage is the CBC’s modular design making it a huge benefit for facilities in need of fast and efficient setup and integration into their system. This modular design also contributes to the quick belt replacement during the rare occasions when maintenance is needed on the belt.